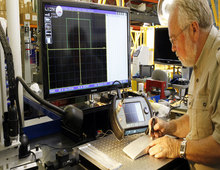

We can provide Eddy Current training suitable for PCN/EN473/ISO 9712 Levels 1, 2, and 3, and ASNT Level 3. Alternatively we can provide training suitable for candidates working to an employer written practice based on SNT-TC-1A; EN4179 and NAS410. Eddy Current Testing is separated into three specific product sectors for certification purposes: Welds, Wrought Products (Forgings), and Tubes.

Below is an example of a syllabus that is used for Eddy Current training courses (we can make changes to a syllabus to satisfy the requirements of a specific written practice if necessary):

Level I

General Theory:

- Brief History of Testing

- Basic Principles of Testing

- Generation of Eddy Currents by means of an AC field

- Effect of fields created by Eddy Currents

- Effect of change of impedance on instrumentation

- Terminology and units

- Principles of magnetisation.

- Magnetisation

- electromagnetism theory

- Flux leakage theory and principle

- Readout Mechanism

- Types of Eddy Current Sensing Elements

- Types of Flux Leakage Sensing Elements

- Safety as applicable to Eddy Current Testing and Electrical Safety

Specific Theory:

Application of the Method and use of Codes, Specifications and Procedures, applicable to the Company, including the relevant control checks.

Level II

General Theory:

- Review of Electromagnetic Theory

- Factors that affect Coil Impedance

- Factors that affect Flux Leakage Fields

- Signal-to-Noise Ratio

- Selection of Test Frequency

- Selection of Method of Magnetisation for Flux

- Leakage Testing

- Coupling

- Field Strength and Its Selection

- Field Orientation for Flux Leakage Testing

- Instrument Design Consideration

- Safety as applicable to Eddy Current Testing and Electrical Safety

General Theory:

Application of the Method to the Specific requirements of the Company, in particular making reference to those Codes, Specifications and Procedures used by the Company, including the relevant control checks.

Coding for ET Training Courses

INTRO/PRAC4 - 5 Days Practical Introduction to Eddy Current Testing (40 Hours)

General Theory:

- ETW4 - Half Day Refresher Course for ET Welds (4 Hours)

- ETW8 - Full Day Refresher Course for ET Welds (8 Hours)

- ETW40 - 5 Days Course for ET Welds suitable for PCN/SNT Level 1 (40 Hours)

- ETW80 - 10 Days Course for ET Welds suitable for PCN/SNT Level 2 Direct (80 Hours)

Wrought Products (Forgings) Specific

- ETWP4 - Half Day Refresher Course for ET Forgings (4 Hours)

- ETWP8 - Full Day Refresher Course for ET Forgings (8 Hours)

- ETWP40 - 5 Days Course for ET Forgings suitable for PCN/SNT Level 1 (40 Hours)

- ETWP80 - 10 Days Course for ET Forgings suitable for PCN/SNT Level 2 Direct (80 Hours)

Tube Testing Specific

- ETTT40 - 5 Days Course for ET Tube Testing suitable for SNT/PCN (40 Hours)

- ETTT80 - 10 Days Course for ET Tube Testing suitable for SNT/PCN Level 2 Direct (80 Hours)

Please note, there is a further charge if you require examination at the end of your training course, look at the ET examination page for details.

Eddy Current courses are available at the Penistone Training Centre on request. We can provide onsite training for your NDT personnel on request.